Capacitors are common components of electronic circuits, used almost as frequently as resistors. The basic difference between the two is the fact that capacitor resistance (called reactance) depends on the frequency of the signal passing through the item. The symbol for reactance is Xc and it can be calculated using the following formula:

f representing the frequency in Hz and C representing the capacitance in Farads.

A capacitor has an infinitely high reactance for direct current, because f=0.

Capacitors are used in circuits for many different purposes. They are common components of filters, oscillators, power supplies, amplifiers, etc.

The basic characteristic of a capacitor is its capacity - the higher the capacity, the higher is the amount of electricity it can hold. Capacity is measured in Farads (F). As one Farad represents fairly high capacity, smaller values such as microfarad (µF), nanofarad (nF) and picofarad (pF) are commonly used. As a reminder, relations between units are:

1F=106µF=109nF=1012pF,

Capacitors are used in circuits for many different purposes. They are common components of filters, oscillators, power supplies, amplifiers, etc.

The basic characteristic of a capacitor is its capacity - the higher the capacity, the higher is the amount of electricity it can hold. Capacity is measured in Farads (F). As one Farad represents fairly high capacity, smaller values such as microfarad (µF), nanofarad (nF) and picofarad (pF) are commonly used. As a reminder, relations between units are:

1F=106µF=109nF=1012pF,

Capacitors come in various shapes and sizes, depending on their capacity, working voltage, type of insulation, temperature coefficient and other factors

Capacitor types

Electrolytic

Electrolytic capacitors are Made of electrolyte, basically conductive salt in solvent. Aluminum electrodes are used by using a thin oxidation membrane. Most common type, polarized capacitor.most used Ripple filters, timing circuits. Cheap, readily available, good for storage of charge (energy). Not very accurate, marginal electrical properties, leakage, drifting, not suitable for use in HF (High Frequency) circuits, available in very small or very large values in uF.

The most important characteristic of electrolytic capacitors is that they have polarity. They have a positive and a negative electrode. This means that it is very important which way round they are connected. they will explode if the rated working voltage is exceeded or polarity is reversed, so be careful. Tantalum

Made of Tantalum Pentoxide. They are electrolytic capacitors but used with a material called tantalum for the electrodes. Superior to electrolytic capacitors, excellent temperature and frequency characteristics. When tantalum powder is baked in order to solidify it, a crack forms inside. An electric charge can be stored on this crack. Like electrolytic, tantalum's are polarized so watch the '+' and '-' indicators. Tantalum capacitors are a little bit more expensive than aluminum electrolytic capacitors. Capacitance can change with temperature as well as frequency, and these types are very stable. Therefore, tantalum capacitors are used for circuits which demand high stability in the capacitance values. Also, it is said to be common sense to use tantalum capacitors for analog signal systems, because the current-spike noise that occurs with aluminum electrolytic capacitors does not appear. Aluminum electrolytic capacitors are fine if you don't use them for circuits which need the high stability characteristics of tantalum capacitors.

Polyester Film

This capacitor uses a thin polyester film as a dielectric. Not as high a tolerance as polypropylene, but cheap and handy, temperature stable, readily available, widely used. Tolerance is approx 5% to 10%. Can be quite large depending on capacity or rated voltage and so may not be suitable for all applications. Temperature stability is poorer than paper capacitors. Usable at low (AC power) frequencies, but inappropriate for RF applications due to excessive dielectric heating.

Polypropylene

This capacitor uses thin polyester film as the dielectric.They are not high tolerance, but they are cheap and handy.No polarity, mainly used when a higher tolerance is needed then polyester caps can offer. This polypropylene film is the dielectric.Very little change in capacitance when these capacitors are used in applications within frequency range 100KHz. Tolerance is about 1%.

Very small values are available.

Polystyrene

No polarity, is used as a dielectric. Constructed like a coil inside so not suitable for high frequency applications. Well used in filter circuits or timing applications using a couple hundred KHz or less. Electrodes may be reddish of color because of copper leaf used or silver when aluminum foil is used for electrodes.

Excellent general purpose plastic film capacitor. Excellent stability, low moisture pick-up and a slightly negative temperature coefficient that can be used to match the positive temperature co-efficient of other components. Ideal for low power RF and precision analog applications

Metalized Polyester Film

No polarity, dielectric made of Polyester or DuPont trade name "Mylar". Good quality, low drift, temperature stable. Because the electrodes are thin they can be made very very small. Good all-round capacitor.Care is necessary, because the component lead easily breaks off from these capacitors. Once lead has come off, there is no way to fix it. It must be discarded.

Ceramic

constructed with materials such as titanium acid barium for dielectric. Internally these capacitors are not constructed as a coil, so they are well suited for use in high frequency applications. Typically used to by-pass high frequency signals to ground. They are shaped like a disk, available in very small capacitance values and very small sizes. Together with the electrolytic the most widely available and used capacitor around. Comes in very small size and value, very cheap, reliable. Subject to drifting depending on ambient temperature. NPO types are the temperature stable types. They are identified by a black stripe on top.

Epoxy

Manufactured using an epoxy dipped polymers as a protective coating. Widely available, stable, cheap. Can be quite large depending on capacity or rated voltage and so may not be suitable for all applications.

Multilayer Ceramic

Dielectric is made up of many layers. Small in size, very good temperature stability, excellent frequency stable characteristics. Used in applications to filter or bypass the high frequency to ground. They don't have a polarity. Multilayer caps suffer from high-Q internal (parallel) resonances - generally in the VHF range. The CK05 style 0.1uF/50V caps for example resonate around 30MHz. The effect of this resonance is effectively no apparent capacitance near the resonant frequency.

As with all ceramic capacitors, be careful bending the legs or spreading them apart to close to the disc body or they may get damaged.

As with all ceramic capacitors, be careful bending the legs or spreading them apart to close to the disc body or they may get damaged.

Silver-Mica

Mica is used as a dielectric. Used in resonance circuits, frequency filters, and military RF applications.

Highly stable, good temperature coefficient, excellent for endurance because of their frequency characteristics, no large values, high voltage types available, can be expensive but worth the extra dimes.the dielectric material (mica) is inert. It does not change physically or chemically with age and it has good temperature stability. Very resistant to corona damage Silver mica capacitors have the above mentioned advantages. In addition, they have much reduced moisture infiltration.Higher cost

Highly stable, good temperature coefficient, excellent for endurance because of their frequency characteristics, no large values, high voltage types available, can be expensive but worth the extra dimes.the dielectric material (mica) is inert. It does not change physically or chemically with age and it has good temperature stability. Very resistant to corona damage Silver mica capacitors have the above mentioned advantages. In addition, they have much reduced moisture infiltration.Higher cost

Adjustable Capacitors

these capacitors have a rotating plate (which can be rotated to change the capacitance) separated from a fixed plate by a dielectric medium Also called trimmer capacitors or variable capacitors. It uses ceramic or plastic as a dielectric.

Most of them are color coded to easily recognize their tunable size. The ceramic type has the value printed on them.

Colors are: yellow (5pF), blue (7pF), white (10pF), green (30pF), brown (60pf).

Most of them are color coded to easily recognize their tunable size. The ceramic type has the value printed on them.

Colors are: yellow (5pF), blue (7pF), white (10pF), green (30pF), brown (60pf).

Tuning or 'air-core' capacitors.

A variable capacitor is a capacitor whose capacitance may be intentionally and repeatedly changed mechanically or electronically. Variable capacitors are often used in L/C circuits to set the resonance frequency, e.g. to tune a radio (therefore they are sometimes called tuning capacitors), or as a variable reactance, They use the surrounding air as a dielectric.

Paper Capacitors

Dielectric used Paper or oil-impregnated paper.Impregnated paper was extensively used for older capacitors, using wax, oil, or epoxy as an impregnant. Oil-Kraft paper capacitors are still used in certain high voltage applications. Has mostly been replaced by plastic film capacitors.Large size. Also, paper is highly hygroscopic, absorbing moisture from the atmosphere despite plastic enclosures and impregnates. Absorbed moisture degrades performance by increasing dielectric losses (power factor) and decreasing insulation resistance.

Glass Capacitors

Similar to Mica Capacitors. Stability and frequency characteristics are better than silver mica capacitors. Ultra-reliable, ultra-stable, and resistant to nuclear radiation.High cost.

Lithium Ion Capacitors

Dielectric used Lithium ion.The Lithium Ion Capacitors have a higher Power Density as compared to batteries and LIC’s are safer in use than LIB’s in which thermal runaway reactions may occur. Compared to Electric Double Layer Capacitor (EDLC), the LIC has a higher output voltage. They both have similar Power Densities, but Energy Density of an LIC is much higher.

Electrolytic double-layer capacitors (EDLC) Supercapacitors

Dielectric used Thin Electrolyte layer and Activated Carbon.Extremely large capacitance to volume ratio, small size, low ESR. Available in hundreds, or thousands, of farads. A relatively new capacitor technology. Often used to temporarily provide power to equipment during battery replacement. Can rapidly absorb and deliver larger currents than batteries during charging and discharging, making them valuable for hybrid vehicles. Polarized, low operating voltage (volts per capacitor cell). Groups of cells are stacked to provide higher overall operating voltage.

Vacuum Capacitors

Vacuum capacitors use highly evacuated glass or ceramic chamber with concentric cylindrical electrodes. Extremely low loss. Used for high voltage high power RF applications, such as transmitters and induction heating where even a small amount of dielectric loss would cause excessive heating. Can be self-healing if arc-over current is limited.

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.

Series connection is also used to adapt electrolytic capacitors for AC use.

Symbols for capacitors

Series or parallel arrangements

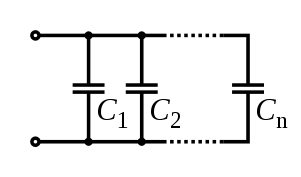

For capacitors in parallel

Capacitors in a parallel configuration each have the same potential difference (voltage). Their total capacitance (Ceq) is given by:

The reason for putting capacitors in parallel is to increase the total amount of charge stored. In other words, increasing the capacitance also increases the amount of energy that can be stored.

For capacitors in series

The current through capacitors in series stays the same, but the voltage across each capacitor can be different. The sum of the potential differences (voltage) is equal to the total voltage. Their total capacitance is given by:

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.

0 comments:

Post a Comment