This is about Electronic hobby circuit, some of the most useful component data, technical information, electronic software, and electronic lesson.

Pages

Stereo preamplifier using LM381

High gain - 112 dB open loop

Single supply operation

Wide supply range 9V-40V

Power supply rejection - 120 dB

Large output voltage swing (VCC - 2V)p-p

Wide bandwidth 15 MHz unity gain

Power bandwidth 75 kHz, 20 Vp-p

Internally compensated

Short circuit protected

Varicap Diode

varicap diodes are a particularly useful form of semiconductor diode. Finding uses in many applications where electronically controlled tuning of resonant circuits is required, for items such as oscillators and filters,

Zener diode

Zener diode is a type of diode that permits current in the forward direction like a normal diode, but also in the reverse direction if the voltage is larger than the breakdown voltage known as "Zener knee voltage" or "Zener voltage".

Zener diode is a type of diode that permits current in the forward direction like a normal diode, but also in the reverse direction if the voltage is larger than the breakdown voltage known as "Zener knee voltage" or "Zener voltage".PCB Artist 1.3.1

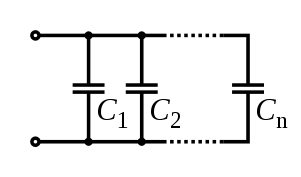

Capacitors

Capacitors are used in circuits for many different purposes. They are common components of filters, oscillators, power supplies, amplifiers, etc.

The basic characteristic of a capacitor is its capacity - the higher the capacity, the higher is the amount of electricity it can hold. Capacity is measured in Farads (F). As one Farad represents fairly high capacity, smaller values such as microfarad (µF), nanofarad (nF) and picofarad (pF) are commonly used. As a reminder, relations between units are:

1F=106µF=109nF=1012pF,

As with all ceramic capacitors, be careful bending the legs or spreading them apart to close to the disc body or they may get damaged.

Highly stable, good temperature coefficient, excellent for endurance because of their frequency characteristics, no large values, high voltage types available, can be expensive but worth the extra dimes.the dielectric material (mica) is inert. It does not change physically or chemically with age and it has good temperature stability. Very resistant to corona damage Silver mica capacitors have the above mentioned advantages. In addition, they have much reduced moisture infiltration.Higher cost

Most of them are color coded to easily recognize their tunable size. The ceramic type has the value printed on them.

Colors are: yellow (5pF), blue (7pF), white (10pF), green (30pF), brown (60pf).

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.

Capacitors are combined in series to achieve a higher working voltage, for example for smoothing a high voltage power supply. The voltage ratings, which are based on plate separation, add up. In such an application, several series connections may in turn be connected in parallel, forming a matrix. The goal is to maximize the energy storage utility of each capacitor without overloading it.Resistors

the type of resistors....

Carbon composition

Carbon composition resistors consist of a solid cylindrical resistive element with embedded wire leads or metal end caps to which the lead wires are attached. The body of the resistor is protected with paint or plastic.the lead wires were wrapped around the ends of the resistance element rod and soldered. The completed resistor was painted for color coding of its value.

The resistive element is made from a mixture of finely ground (powdered) carbon and an insulating material (usually ceramic). A resin holds the mixture together. The resistance is determined by the ratio of the fill material (the powdered ceramic) to the carbon. Higher concentrations of carbon, a weak conductor, result in lower resistance.

*carbon composition resistors will change value when stressed with over-voltages*

They are still available, but comparatively quite costly. Values ranged from fractions of an ohm to 22 meg ohms.

Carbon film

A carbon film is deposited on an insulating substrate, and a helix cut in it to create a long, narrow resistive path. Varying shapes, coupled with the resistivity of carbon, (ranging from 90 to 400 nΩm) can provide a variety of resistances.Carbon film resistors feature a power rating range of 0.125 W to 5 W at 70 °C. Resistances available range from 1 ohm to 10 megohm. The carbon film resistor can operate between temperatures of -55 °C to 155 °C. It has 200 to 600 volts maximum working voltage range.

Thick and thin film

Most SMD (surface mount device) resistors today are of this type. The principal difference between thin film and thick film resistors is not the actual thickness of the film, but rather how the film is applied to the cylinder (axial resistors) or the surface (SMD resistors).

Thin film resistors are made by sputtering (a method of vacuum deposition) the resistive material onto an insulating substrate. The film is then etched in a similar manner to the old (subtractive) process for making printed circuit boards; that is, the surface is coated with a photo-sensitive material, then covered by a pattern film, irradiated with ultraviolet light, and then the exposed photo-sensitive coating is developed, and underlying thin film is etched away.

Because the time during which the sputtering is performed can be controlled, the thickness of the thin film can be accurately controlled. The type of material is also usually different consisting of one or more ceramic (cermet) conductors such as tantalum nitride (TaN), ruthenium dioxide (RuO2), lead oxide (PbO), bismuth ruthenate (Bi2Ru2O7), nickel chromium (NiCr), and/or bismuth iridate (Bi2Ir2O7).

The resistance of both thin and thick film resistors after manufacture is not highly accurate; they are usually trimmed to an accurate value by abrasive or laser trimming. Thin film resistors are usually specified with tolerances of 0.1, 0.2, 0.5, or 1%, and with temperature coefficients of 5 to 25 ppm/K.

Thick film resistors may use the same conductive ceramics, but they are mixed with sintered (powdered) glass and some kind of liquid so that the composite can be screen-printed. This composite of glass and conductive ceramic (cermet) material is then fused (baked) in an oven at about 850 °C.

Thick film resistors, when first manufactured, had tolerances of 5%, but standard tolerances have improved to 2% or 1% in the last few decades. Temperature coefficients of thick film resistors are high, typically ±200 or ±250 ppm/K; a 40 kelvin (70 °F) temperature change can change the resistance by 1%.

Thin film resistors are usually far more expensive than thick film resistors. For example, SMD thin film resistors, with 0.5% tolerances, and with 25 ppm/K temperature coefficients, when bought in full size reel quantities, are about twice the cost of 1%, 250 ppm/K thick film resistors.

Metal film

Metal film resistors are usually coated with nickel chromium (NiCr), but might be coated with any of the cermet materials listed above for thin film resistors. Unlike thin film resistors, the material may be applied using different techniques than sputtering (though that is one such technique). Also, unlike thin-film resistors, the resistance value is determined by cutting a helix through the coating rather than by etching. (This is similar to the way carbon resistors are made.) The result is a reasonable tolerance (0.5, 1, or 2%) and a temperature coefficient of (usually) 25 or 50 ppm/K.

Wire wound

Wire wound resistors are commonly made by winding a metal wire, usually nichrome, around a ceramic, plastic, or fiberglass core. The ends of the wire are soldered or welded to two caps or rings, attached to the ends of the core. The assembly is protected with a layer of paint, molded plastic, or an enamel coating baked at high temperature. Wire leads in low power wire wound resistors are usually between 0.6 and 0.8 mm in diameter and tinned for ease of soldering. For higher power wire wound resistors, either a ceramic outer case or an aluminum outer case on top of an insulating layer is used. The aluminum-cased types are designed to be attached to a heat sink to dissipate the heat; the rated power is dependent on being used with a suitable heat sink, e.g., a 50 W power rated resistor will overheat at a fraction of the power dissipation if not used with a heat sink. Large wire wound resistors may be rated for 1,000 watts or more.

Because wire wound resistors are coils they have more undesirable inductance than other types of resistor, although winding the wire in sections with alternately reversed direction can minimize inductance.

Foil resistor

The primary resistance element of a foil resistor is a special alloy foil several micrometres thick. Since their introduction in the 1960s, foil resistors have had the best precision and stability of any resistor available. One of the important parameters influencing stability is the temperature coefficient of resistance (TCR). The TCR of foil resistors is extremely low, and has been further improved over the years. One range of ultra-precision foil resistors offers a TCR of 0.14 ppm/°C, tolerance ±0.005%, long-term stability (1 year) 25 ppm, (3 year) 50 ppm (further improved 5-fold by hermetic sealing), stability under load (2000 hours) 0.03%, thermal EMF 0.1 μV/°C, noise -42 dB, voltage coefficient 0.1 ppm/V, inductance 0.08 μH, capacitance 0.5 pF

Ammeter shunts

An ammeter shunt is a special type of current-sensing resistor, having four terminals and a value in milliohms or even micro-ohms. Current-measuring instruments, by themselves, can usually accept only limited currents. To measure high currents, the current passes through the shunt, where the voltage drop is measured and interpreted as current. A typical shunt consists of two solid metal blocks, sometimes brass, mounted on to an insulating base. Between the blocks, and soldered or brazed to them, are one or more strips of low temperature coefficient of resistance (TCR) manganin alloy. Large bolts threaded into the blocks make the current connections, while much-smaller screws provide voltage connections. Shunts are rated by full-scale current, and often have a voltage drop of 50 mV at rated current.

Grid resistor

In heavy-duty industrial high-current applications, a grid resistor is a large convection-cooled lattice of stamped metal alloy strips connected in rows between two electrodes. Such industrial grade resistors can be as large as a refrigerator; some designs can handle over 500 amperes of current, with a range of resistances extending lower than 0.04 ohms. They are used in applications such as dynamic braking and load banking for locomotives and trams, neutral grounding for industrial AC distribution, control loads for cranes and heavy equipment, load testing of generators and harmonic filtering for electric substations

Hire is the symbol,

The resistor is generally labeled by the letter "R" followed by a number, e.g., R1, R2, etc. The resistance value, measured in ohms, may also be indicated. If the resistance is not indicated, you can determine it by observing the color coding used on most resistors.

The resistor is generally labeled by the letter "R" followed by a number, e.g., R1, R2, etc. The resistance value, measured in ohms, may also be indicated. If the resistance is not indicated, you can determine it by observing the color coding used on most resistors.Color Code for Resistors.

Electronics Workbench Multisim (Education Version)

Electronic Design Studio

A Digital Circuit Simulator

Circuit Shop 2.06

Circuit Shop is a graphical CAD tool to allow simple digital and analog electronic circuits to be constructed and analyzed. It includes: Drawing tools to construct simple electronic circuit schematics consisting of digital and analog devices such as logic gates, flip-flops, op amps, dependent sources, ICs and transistors. Version 2.06 features updated help, improved drawing behaviour, and a library of audio visual component custom symbols.

download

CircuitMaker Student Edition

CircuitMaker Student Edition is a free download, although it is no longer supported by the original developer. It still works fine under Windows XP.

download

This new Student Version of CircuitMaker will be a great asset to those studying electronics, engineering, physics and even math, because it gives students access to industry-level circuit design and simulation for free,? said Russell Arnold, director of sales and marketing at MicroCode. ?Using CircuitMaker, students can design electronic circuits, then test and troubleshoot them right on the computer. There are no expensive parts or equipment to buy, and they can make changes to their circuits and see the results instantly.

The CircuitMaker software provides a ?Virtual Electronics Lab?? where users can freely experiment with electronic circuits and learn how to create working electronic devices. Users can design basic to advanced circuits, like those used in radios, TVs and computers. The software provides a comprehensive library of devices to choose from, and has various ?virtual instruments? like oscilloscopes and multimeters that allow users to measure, test and troubleshoot the circuits they create

Rectification

For most power applications, half-wave rectification is insufficient for the task. The harmonic content of the rectifier's output waveform is very large and consequently difficult to filter. Further more, AC power source only works to supply power to the load once every half-cycle, meaning that much of its capacity is unused. Half-wave rectification is, however, a very simple way to reduce power to a resistive load.

For most power applications, half-wave rectification is insufficient for the task. The harmonic content of the rectifier's output waveform is very large and consequently difficult to filter. Further more, AC power source only works to supply power to the load once every half-cycle, meaning that much of its capacity is unused. Half-wave rectification is, however, a very simple way to reduce power to a resistive load.Full-wave rectifier circuit

(Center-tap design)

This circuit's operation is easily understood one half-cycle at a time. Consider the first half-cycle, when the source voltage polarity is positive (+) on top and negative (-) on bottom. At this time, only the top diode is conducting; the bottom diode is blocking current, and the load "sees" the first half of the sine wave, positive on top and negative on bottom. Only the top half of the transformer's secondary winding carries current during this half-cycle,

During the next half-cycle, the AC polarity reverses. Now, the other diode and the other half of the transformer's secondary winding carry current while the portions of the circuit formerly carrying current during the last half-cycle sit idle. The load still "sees" half of a sine wave, of the same polarity as before: positive on top and negative on bottom:

Full-wave rectifier circuit

(Bridge design)

Current directions in the full-wave bridge rectifier circuit are as follows for each half-cycle of the

AC waveform

Semiconductor diode

Permitted direction of electron flow

Permitted direction of electron flowWhen placed in a simple battery-lamp circuit, the diode will either allow or prevent current through the lamp, depending on the polarity of the applied voltag

Current permitted -Diode is forward-biased

Current permitted -Diode is forward-biased  Current prohibited -Diode is reverse-biased

Current prohibited -Diode is reverse-biasedWhen the polarity of the battery is such that electrons are allowed to flow through the diode, the diode is said to be forward-biased. Conversely, when the battery is "backward" and the diode blocks current, the diode is said to be reverse-biased. A diode may be thought of as a kind of switch: "closed" when forward-biased and "open" when reverse-biased.

For silicon diodes, the typical forward voltage is 0.7 volts, nominal. For germanium diodes, the forward voltage is only 0.3 volts. The chemical constituency of the P-N junction comprising the diode accounts for its nominal forward voltage figure, which is why silicon and germanium diodes have such different forward voltages. Forward voltage drop remains approximately equal for a wide range of diode currents, meaning that diode voltage drop not like that of a resistor or even a normal (closed) switch. For most purposes of circuit analysis, it may be assumed that the voltage drop across a conducting diode remains constant at the nominal figure and is not related to the amount of current going through it.

For silicon diodes, the typical forward voltage is 0.7 volts, nominal. For germanium diodes, the forward voltage is only 0.3 volts. The chemical constituency of the P-N junction comprising the diode accounts for its nominal forward voltage figure, which is why silicon and germanium diodes have such different forward voltages. Forward voltage drop remains approximately equal for a wide range of diode currents, meaning that diode voltage drop not like that of a resistor or even a normal (closed) switch. For most purposes of circuit analysis, it may be assumed that the voltage drop across a conducting diode remains constant at the nominal figure and is not related to the amount of current going through it.

Diodes with PIV ratings in the many thousands of volts are available for modest prices.

REVIEW:

A diode is an electrical component acting as a one-way valve for current.

When voltage is applied across a diode in such a way that the diode allows current, the diode is said to be forward-biased.

When voltage is applied across a diode in such a way that the diode prohibits current, the diode is said to be reverse-biased.

The voltage dropped across a conducting, forward-biased diode is called the forward voltage.

Forward voltage for a diode varies only slightly for changes in forward current and temperature, and is fixed principally by the chemical composition of the P-N junction.

Silicon diodes have a forward voltage of approximately 0.7 volts.

Germanium diodes have a forward voltage of approximately 0.3 volts.

The maximum reverse-bias voltage that a diode can withstand without "breaking down" is called the Peak Inverse Voltage, or PIV rating.